Metal Welding (Svařování kovů): A Guide to Basic Methods and Techniques

Metal welding is one of the most important processes in industry, construction, and home workshops. It is a technology for joining metal materials using heat, pressure, or a combination of both, creating a strong and permanent bond. The history of welding dates back to the era of blacksmiths, but modern methods developed primarily in the 19th and 20th centuries with the discovery of the electric arc and the industrial revolution.

Today, there are many types of welding, but the most common are arc methods: MMA (coated electrode, also known as stick welding), MIG/MAG, TIG, and oxy-acetylene welding. Each method has its advantages, disadvantages, and ideal applications. Let's take a closer look at them.

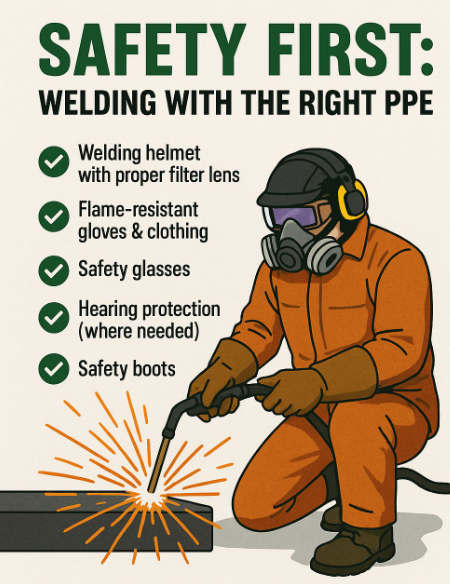

Safety in Welding

Before diving into the techniques, it is crucial to emphasize safety. Welding produces intense light, heat, sparks, and fumes that can cause burns, eye damage, respiratory issues or death.

Always use a welding helmet with auto-darkening lens, gloves, flame-resistant clothing, a respirator, and work in a well-ventilated area.

Basic Types of Weld Joints

Proper joint preparation is essential before welding. The most common types include butt joint, T-joint, lap joint, and edge joint.

Correct preparation (e.g., beveling edges) ensures the strength and quality of the weld.

Most Common Welding Methods

1. MMA (Coated Electrode, Shielded Metal Arc Welding)

One of the oldest and most versatile methods. It uses a coated electrode that melts to form the arc. The coating produces protective gas and slag.

Advantages: Inexpensive, suitable for outdoor use (wind-resistant), works on dirty or rusty materials.

Disadvantages: Slower, more slag to remove, requires experience.

Applications: Construction, repairs, thick steels.

2. MIG/MAG (Metal Inert/Active Gas)

The most widespread industrial method. A continuous wire is fed automatically, protected by gas (inert for MIG, active for MAG).

Advantages: Fast, easy to control, clean welds, suitable for thin and thick materials.

Disadvantages: Sensitive to wind (requires gas), more expensive equipment.

Applications: Automotive industry, manufacturing, steel, aluminum, stainless steel.

3. TIG (Tungsten Inert Gas)

A precision method using a non-consumable tungsten electrode and manually added filler wire. Protected by inert gas (argon).

Advantages: Highest weld quality, clean and aesthetic, ideal for thin materials and exotic metals.

Disadvantages: Slower, requires high skill, more expensive.

Applications: Aerospace, food industry, stainless steel, aluminum, titanium.

4. Oxy-Acetylene Welding

An older method using a flame from acetylene and oxygen.

Advantages: Portable, suitable for cutting and welding thin sheets.

Disadvantages: Slower, higher risk of material distortion.

Applications: Repairs, artistic work.

Conclusion

Metal welding is a fascinating field that combines technique, skill, and safety. For beginners, MIG/MAG is ideal due to its ease of use, while professionals often choose TIG for precision work. The choice of method depends on the material, thickness, environment, and required quality.