How Many Hours Can an Excavator Work Before Needing Major Repairs? – Real Numbers from the Czech Republic (2025)

Here's what actually happens in the real world, based on what Czech mechanics and quarry owners see every day:

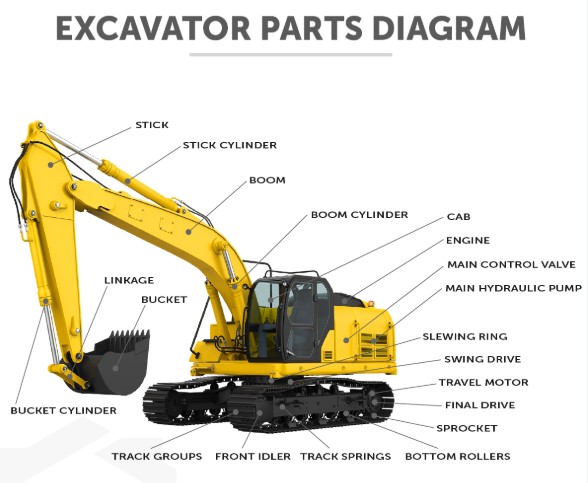

- Engine (full overhaul): With good maintenance and original oils/filters, most modern CAT, Komatsu, or Volvo engines run 10,000–16,000 hours before the first major rebuild. Many 20-ton machines easily pass 14,000 hours.

- Hydraulic pumps: The most common big expense. They usually last 8,000–12,000 hours on normal jobs, but in quarries and gravel pits they often die already at 7,000–9,000 hours.

- Swing bearing / slew ring: 10,000–18,000 hours. When it goes, you're looking at a full replacement that costs 250,000–600,000 CZK depending on machine size.

- Undercarriage (tracks, rollers, idlers): 3,000–7,000 hours. In rock quarries you'll be lucky to get 3,500–4,500 hours; on regular construction sites 5,000–7,000 is normal.

- Bucket: 2,000–6,000 hours. Digging in sand = longer life, digging in stone = much shorter.

- Boom and arm (the big arms): 15,000–25,000+ hours. They usually outlive the rest of the machine; you just weld cracks as they appear.

- Main control valve: 8,000–14,000 hours. Repair or overhaul costs 80,000–200,000 CZK.

- Whole machine (economic life): 12,000–20,000 hours. After about 15,000–18,000 hours the repair bills usually become higher than the value of the machine itself.

Quick real-life examples

A 20-ton CAT 320 or Komatsu PC210 doing normal construction work with proper service regularly reaches 12,000–15,000 hours before the first engine overhaul. A 30-ton machine in a quarry will chew through an undercarriage in 3,500–4,500 hours and pumps in 7,000–9,000 hours. Small 8-ton machines (Kubota, Bobcat, Takeuchi) often go past 10,000 hours with almost no big repairs because the work is lighter.

What affects it the most

Good regular maintenance adds 30–50 % life. Working in rock instead of soil can cut life in half. Bad operators who overload or run high revs all day shorten everything by 20–40 %. Using cheap aftermarket parts instead of originals can cost you 2,000–5,000 hours.

Bottom line for Czech owners

Up to 8,000–10,000 hours → mostly just routine service. 10,000–15,000 hours → start budgeting for big items (pumps, slew ring).

Above 18,000 hours → the machine is usually living on borrowed time and repairs stop making financial sense.

Tell us your exact model and current hours and we will tell you what's coming next and roughly how much it will cost. Welding heavy machinery and excavators is one of our specialties and passion.

Svářeč Třebíč can provide mobile welding repair service to your region.