10 Mistakes That Lead Welders to Close Their Businesses

Small welding/fabrication businesses (kovovýroba, mobilní sváření) in Czech Republic, including in regions like Vysočina/Třebíč, often fail despite a relatively strong metalworking/machinery sector (automotive supply chain, agricultural equipment, construction).

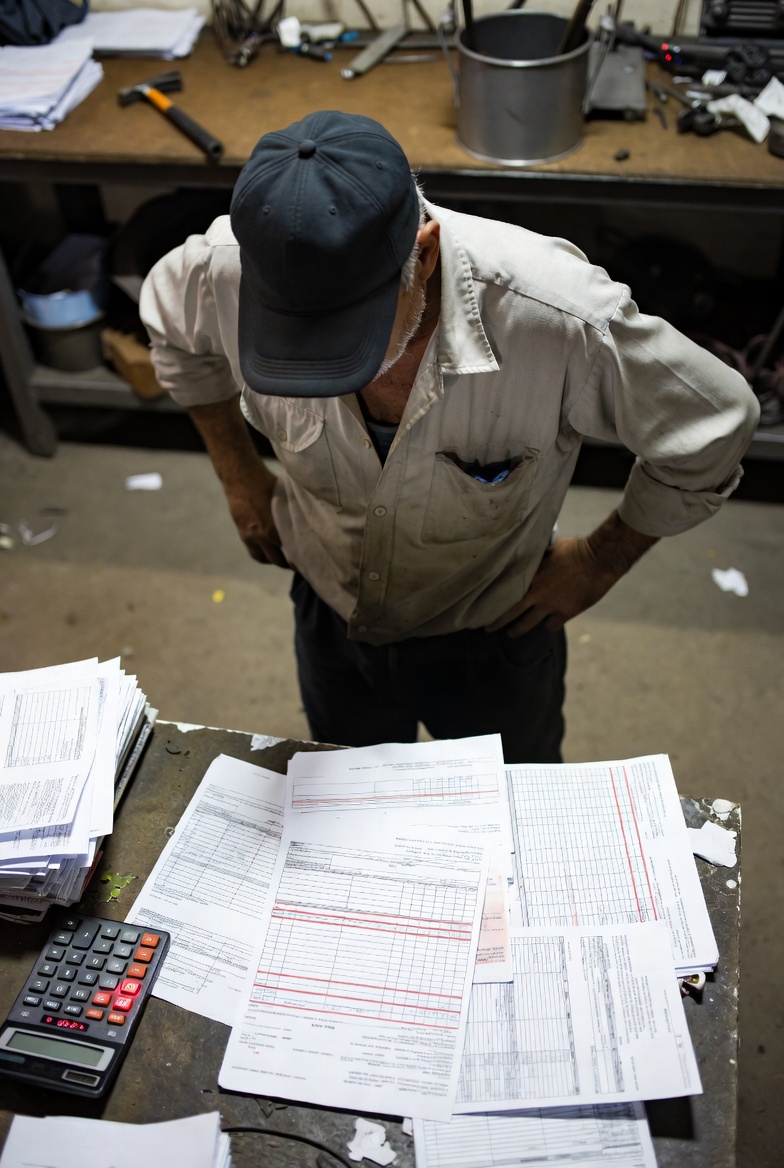

Closures stem primarily from internal issues rather than zero demand: high operational costs (energy, labor, materials), bureaucracy, cash flow problems, and management errors. In 2023, over 16,000 firms closed (record levels), with many sole traders in trades simply ceasing activity—net loss of hundreds of thousands of entrepreneurs in recent years. Nearly half of small firms (<50 employees) wouldn't recommend entrepreneurship due to costs and stress.

Formal insolvencies are rarer for micro-firms (many are OSVČ sole traders), but indirect hits come from client bankruptcies (e.g., construction/agricultural businesses delays payments) or broader industry pressures like those at Liberty Ostrava (high energy/labor costs, modernization failures).

Top 10 Mistakes Leading welders to Failure

(For Czech Mobile Welders and Fabricators)

These draw from common business failure data, technical welding pitfalls, and sector reports. Many overlap with general small trades:

1. Underpricing or poor cost calculation — Charging too low to win jobs ignores full costs (fuel, travel, consumables, time, VAT, social/health contributions ~40%+ of labor). Results in no profit, especially with rising energy/materials prices.

2. Weak financial management/cash flow — Late client payments (common in construction/farms), no reserves for slow seasons, fear of loans. 1/5 small firms lack adequate reserves.

3. Lack of certifications & compliance — No welder quals (EN ISO 9606), company process certs (EN 1090 for structural steel), or safety/insurance. Blocks big contracts (construction, factories) and risks fines/liability.

4. Bureaucracy/tax non-compliance — Poor bookkeeping, VAT issues, high admin burden (costs billions CZK yearly across small firms). Leads to audits/fines.

5. Inconsistent quality or technical errors — Improper joint prep, wrong filler metals/consumables, old/repurposed equipment, inadequate preheat/shielding gas, exceeding equipment ratings. Causes rework, lost reputation, or structural failures.

6. Over-reliance on word-of-mouth/poor marketing — No online presence (Google Business, Firmy.cz, Bazos), inconsistent leads. Hard to compete or fill pipeline in seasonal agri/construction.

7. Solo burnout or no scaling — One-person operation without helpers/apprentices for growth. High physical/mental toll; can't handle volume or emergencies.

8. Lack of diversification/contracts — Dependency on few clients or one sector (e.g., only farms). No formal contracts/invoicing leads to disputes/non-payment.

9. Ignoring safety/environmental regulations — Violations (fumes, fire risks, waste) cause shutdowns, injuries, lawsuits. Strict EU/CZ enforcement.

10. Failure to adapt to costs/competition — High energy/labor/raw material prices, imports from lower-cost countries, or inability to modernize (efficient inverters, mobile generators). Seen in larger closures too.

Why Some Businesses Flourish Despite Challenges

Successful welders/fabricators in Vysočina/Třebíč and similar areas thrive by:

- Niche specialization — less price competition than shop-based fabrication.

- Certifications & quality focus.

- Financial discipline — Accurate pricing (include overhead), prompt invoicing, reserves for winter/slow periods, diversification across multiple industries.

- Reliability & relationships — Fast response, site cleanliness, warranties, networking → word-of-mouth in tight-knit regions.

- Efficiency & modernization — Good welding setup (reliable generator, multi-process welders) reduces downtime/costs.

- Client base management — Mix of small/medium clients; contracts with larger ones; avoid overexposure to volatile sectors.

Tips for welders

- Prioritize certifications early — Get welder quals (CWS-ANB or equivalent) and liability insurance. Display on van/website for trust with factories/construction.

- Price professionally — Calculate hourly/day rates including all costs + margin (20-40%+). Offer value: mobile convenience, same-day response, warranties. Start with assessments/quotes free or low-cost.

- Build financial buffers — Track every expense/income (use simple software). Invoice immediately, require deposits for big jobs, maintain 3-6 months reserves. Use contracts/templates.

- Operational excellence — Invest in quality equipment/consumables; focus on prep, safety (PPE, ventilation), clean work.

- Avoid burnout — Plan for helpers/subcontractors as volume grows. Diversify your client base.

By avoiding underpricing, compliance gaps, and isolation while emphasizing reliability and specialization, your business can grow into a stable local asset. Word-of-mouth spreads fast.